Mechanical Tools And Their Uses

There are many different types of tools.

A carpenter’s toolbox will look different from a plumber’s.

But you’ll find all toolboxes will overlap in areas like measuring, cutting, and gripping.

Most Common Mechanical Tools.

Here’s a list of mechanics tools, divided into three categories.

It gives you an idea of what the hobbyist, Diy expert, and the Pro mechanics toolbox might look like.

Basic Mechanics Tool Set

- Gloves

- Safety glasses

- WD40

- Torque Wrench

- Mobile tool box

- Hammers

- Chisels & Punches

- Wire brush

- Screwdrivers

- Vice grips

- Adjustable wrench’s

- Wrench set

- Socket set

- Oil filter tool

- Oil pan drain

- Funnel

- Floor jack

- Two floor stands

- LED light

- Test light

- Pliers set

- Jump Leads

Gear Head Mechanics Tool Set

- Chest tool box on wheels

- DVOM (Volt meter)

- Fault code reader

- Impact wrench

- Impact sockets

- Power drill

- Drill bit set

- Vernier calipers

- Grinder

- Cheater bars

- Breaker bar

- Hose clamp pliers

- Hose clamps

- Magnetic pick-ups

- Torx set

- Soldering kit

- Wiring repair kit

- G-clamps

- Battery charger

- Tire gauge

- Compressor

- Air gun

- Air ratchet

Professional Mechanics Tool Set

- Fastener bit selection

- Harmonic pullers

- Universal pullers

- Air saw

- Air chisel

- Cut off wheel

- Compression tester

- Fuel pressure tester

- Radiator pressure tester

- Stethoscope

- Diesel leak back tester

- Bushing removal tool

- Brake wind back tool

- Brake bleeding tool

- Brake line flaring tool

- Tap and die set

- Welder

Why I Wear Hand Protection

A mechanics’ hands are pretty tough, but not as tough as some of the chemicals that get on your skin.

While it appears that chemicals like gas and oil don’t hurt your skin on contact, they will damage your hands.

The skin will absorb them, and the liver has to rid the body of the toxins.

Simple latex gloves will protect the skin and the rest of the body from unknown chemicals.

My uncle was a heavy machinery mechanic and never took to wearing gloves.

His hands show it, dry and cracked.

If you use a lot of air tools, like air chisels, impact wrench’s or any device that vibrates,

you’ll need to think about anti-vibration gloves.

Hand-arm vibration syndrome (HAVS) is a condition that affects mechanics or anyone using this type of equipment.

The constant vibration causes hand nerve damage.

It’s a condition that’s uncomfortable, reduces power in the hands, and is irreversible.

This condition isn’t widely known in the industry.

Wearing anti-vibration gloves with air tools or any vibrating tool should be as compulsory as a hard hat on a construction site.

Why I Wear Safety Glasses?

I’ve been working on the shop floor for more than twenty years,

and I’ve seen some accidents that were preventable and predictable and some that weren’t.

Sometimes crap happens, recently I was riding on my lawn tractor,

and a stone flu from under the deck hit the front wheel, rebounded, and struck me square in the eye.

I’ve cut that lawn hundreds of times before with the same mower without one injury, ever.

The message – When working, always wear safety glasses.

Why Wd40 Is My Favourite Tool

This stuff is close to magic. You’ll be amazed what you can fix with wd.

It’s excellent at preventative maintenance, drives out moisture, and protects.

It’s especially useful when working on old cars.

Corroded bolts usually mean busted knuckles, rounded fastener heads, vice grips, blow torch,

hammers, chisels, basically a right pain in the jacksie.

I always have lots of WD on hand. It’s probably the most useful tool in a workshop.

That’s why it’s the first tool on the list.

Is A Torque Wrench Essential?

A torque wrench is a tool that tightens fasteners to an adjustable specific measurement.

All nuts, bolts, and screws will have an exact torque specification set out by the manufacturer.

Over-tightening and under-tightening can cause bolts to break and components to come loose,

which obviously can endanger life if the component is part of the suspension, braking, or steering systems.

Uses:

If you’re removing and fitting wheels, they’ll need to be torqued to specification.

Wheels tightened by feel is OK in an emergency but ideally should be checked and torqued at the earliest opportunity.

A torque wrench is also needed when replacing a water pump, front engine cover, camshaft cover, oil pan, etc.

Over-tightening these components can lead to oil leaks and severe engine damage.

A Tool Box Needs To Be Mobile

When you’re working on a car, it’s more efficient to take all your tools to the vehicle.

If you can’t do that, prepare to burn a lot of time and shoe leather.

Walking over and back to a toolbox all day can be soul-destroying, especially when a job isn’t going your way.

Uses: A small transportable toolbox is perfect for the hobbyist, it keeps everything in one place, and you’ll know where everything is.

More drawers sometimes equal more hiding places for tools.

Not being able to lay your hand on the right tool quickly is annoying.

A good toolbox should have wide storage space for standard tools while not being overly cumbersome.

Best Hammer For A Mechanic

A hammer is a hammer.

Well, not really. A mechanic needs a few different types.

Different metals and components need to be treated differently.

Hammers are graded by type, weight, and material used. A mechanic will typically need 3 to 4 hammers.

A large 3-4 lbs steelhead hammer is excellent for loosening ball joints, especially if you are working on a truck.

The basic Peen hammer will have a ball head on one side and a flat face head.

The peen head was traditionally used to harden the metal.

In the hands of a mechanic, it will likely be used to repair or shape sheet metal, fastener heads, etc.

The peen is the ball of the hammer.

It leaves a smaller witness mark than a flat-faced hammer.

The Rubber Hammer, yea, I know it sounds like a joke, but it’s real.

It’s a metal hammer with a lead-filled head covered in heavy rubber.

It’s used to strike softer materials, like plastic, rubber, and sheet metal.

A mechanic would likely use a rubber hammer to move a component rather than reshape it.

Uses:

Brass or copper head hammers are used in engine and transmission rebuilds.

Brass and copper are soft metals, and that’s important.

These hammers are designed to be used on harder materials,

meaning the hammer face will deform instead of damaging the component.

Hammerheads are commonly made from brass, copper, lead, leather, and plastic.

The striking face of the hammer is often replaceable.

What Chisels Do Mechanics Use?

Chisels are not all the same.

They come in lots of different sizes and have other functions.

Mechanics use what’s known as a cold chisel, named by blacksmiths as it’s the best chisel to cut cold metal.

The striking head is unique in that it’s not heat treated like the shaft and tip.

The softer metal in the head is less likely to shatter, and therefore safer to use.

Uses:

A mechanic will need 3-4 different size cutting chisels, they’re used for a variety of uses.

When working on old cars, often they’ll be used to remove old rusty fasteners, cutting sheet metal, exhaust system repairs, etc.

Punches:

A mechanic will also find plenty of uses for punches of various sizes.

A punch is used in the removal of old bearings and other press-fitted components.

The flat-faced tip instead of a chisel tip is perfect for catching a bearing lip.

Wire Brushes Types And Uses

A wire brush is exactly as its name suggests.

It’s a basic tool that you’ll use every day as a mechanic.

Uses:

Useful for removing rust and dirt from bolt threads before removing them,

cleaning brake components, brake lines, rusty sheet metal, etc.

Wire brushes don’t usually last longer than six months or so.

The wire bristles wear down and become too flexible.

I especially like the wire brush adaptors for the power tools.

They come in all shapes and sizes. You’ll easily get one that’s perfect for the job at hand.

It saves a ton on elbow grease.

Screwdrivers Types And Uses

Can’t be a mechanic without a good selection of screwdrivers, you’ll need a wide variety of Philips (Star) head and flatheads.

Long and short reach and with a magnetic head which is always useful for stray screws.

Shockproof is preferred. You’ll need to hit them with a hammer from time to time.

I don’t have favorite screwdrivers because they tend to wear out, and when they do, they’re useless.

They slip and damage fasteners which make a simple job a bigger one.

What’s A Vice-grips?

I can’t remember not having Vice-grips. I’ve been using them forever.

They are the go-to tool when things turn to s**t.

The original vice grips are an American invention and are simply ingenious.

Uses:

Designed to be an extra hand, it’s used mainly to grip and hold work materials.

Its clever design allows you to adjust, clamp and unclasp the grips using one hand.

The range expanded and came in many variations – chain, clamp, pointy nose, mini, and many other varieties.

I’d say I use my grips every day; it’s a must-have tool.

What’s An Adjustable Wrench?

The adjustable wrench is a toolbox staple. It’s especially popular with plumbers.

Not a tool I would use very often. A mechanic will prefer to have a more precise wrench fit.

The adjustable wrench, although very flexible, can be a little cumbersome to use.

Uses:

The adjustable wrench is a universal wrench. Adjust it to fit any nut or bolt.

They’re a pretty durable kit and can be struck with a hammer when called for.

I use them when working on high-pressure hoses.

The stout jaws fit the wide hose pipe fittings nicely.

A plumber can’t work without adjustable wrenches.

What’s A Wrench Set?

Wrenches are precision tools.

Each one is a fixed size and will only fit its corresponding nut or bolt size.

It is commonly made using industrial-grade chromium-vanadium steel.

The standard wrench has an open end on one side and a box end on the other, known as a combination wrench. The open end is great for easy, fast use, but the grip is compromised.

Every mechanic has skinned his or her knuckles on a slipping open-ended wrench. If you haven’t, you’re not trying hard enough.

The box end offers the best grip and is less likely to damage the fastener head or your knuckles.

In Europe, wrench’s are called spanners, and the box end is called the ring end.

Double ring head, Stubby, Offset, Ratchet, Flare-nut wrench, C-Type, Double open-ended, and lots of other combinations.

Box end wrenches are available in 12 point and 6 point.

The 12 point allows for greater access to a fastener head, the angle of attack is much wider than a 6 point.

The 6 point, however, will often grip the fastener more snugly and is much less likely to ring the fastener head.

Two standards are the norm, and most mechanics will have both—Metric and standard (Imperial).

Metric wrenches are measured in millimeters. Standard sizes in a toolset range from 8mm to 25mm, with

8,10,13,17 being the most popular sizes.

Standard wrench sizes are more popular in the US. You’ll find them on older cars, motorbikes, and lawnmowers.

Popular imperial sizes include 3/8, 7/16, 1/2, 11/16, and 3/4 inches.

Uses:

The wrench is obviously one of the most used tools in a mechanics toolbox.

I use them every day on various jobs, usually fasteners where you can’t fit a ratchet and socket.

What’s A Ratchet & Socket Set?

A ratchet is a tool used to drive sockets.

It is much faster loosening and tightening fasteners than a spanner.

However, it is a lot bulkier.

The ratchet’s great advantage is its flexibility.

A ratchet set will include a range of popular sizes but also long and short extensions.

The set snaps together and allows the mechanic to reach deep between components and manipulate nuts and bolts.

For those really awkward nuts and bolts, the set includes the knuckle.

This nifty kit allows the socket to sit squarely on the fastener while the extension is offset.

Of course, a ratchet set is useless without sockets. And sockets, as you can imagine, come in many different forms.

- Standard

- Deep set,

- Plug sockets

- O2 sockets

- Low profile sockets

- Impact sockets

- Wheel sockets

- Insulated sockets

- Crows feet

Many sockets are available in 1/2 inch, 3/8, and the smallest 1/4 inch drive.

Generally, a 1/2 ratchet drive is used with the 1/2 sockets, but adaptors allow you to mix and match between the sizes.

The combinations are endless, and if you’re working on modern cars, you’ll use most of them and some!

The sockets, just like wrenches, are available in 12 point or six-point, the six offer less flexibility but far greater grip.

The usual standard or metric sizes are also available, and if you’re working on classic cars, you’ll need both.

Avoid if you can using an impact wrench with your regular sockets.

The walls are thinner, and they’ll break or shatter, causing injury.

Uses:

Excellent for removing deep-set fasteners such as spark plugs, header bolts, transmission bolts,

starter motor bolts, anywhere your hand movement is restricted, which on modern cars – anywhere under the hood.

What’s An Oil Filter Tool?

Older style car oil filters are simple metal filters that screw onto an oil filter adaptor on the side of the engine block.

Although oil filters are only fitted hand tight (oil filter tools are not needed for fitting),

the filters do tight over time and so a tool is needed to remove them.

A strap or chain grip may be used for leverage but is only useful when the real estate around the filter is vacant.

If the filter is berried between components, then you’ll need a claw-long extension and ratchet.

It crushes the filter and looks kind of unprofessional but very effective.

Modern car oil filters use a cartridge set up and require a different type of oil filter tool.

Sockets and ratchets are used on later models, and on earlier models,

oil filter removal tools resembling very large sockets were needed.

There are a few different oil filter tools for different applications, and so you’ll need a variety,

a claw, chain or strap, and an oil filter set.

COPIED

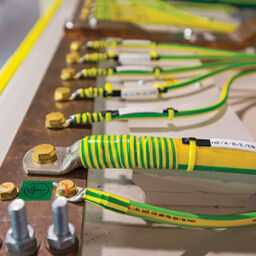

Electrical transformers

We are pleased to have you visit our pages on social networking sites, where we publish exclusive offers on our website.

Our Facebook page here .

Our Twitter account is here .